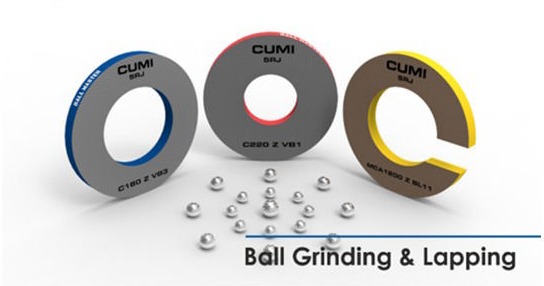

Bearing Ball Grinding Wheels

Precision for High-Quality Bearings

Bearing ball grinding is a crucial process in the manufacturing of high-performance bearing components. Bearing ball grinding wheels are designed specifically to meet the demanding requirements of precision and consistency necessary for producing high-quality bearing balls.

How Bearing Ball Grinding Works

Bearing ball grinding involves the use of specialized grinding wheels to achieve precise dimensions and surface finishes on spherical bearing balls. These wheels are engineered to deliver:

Uniform Grinding: Ensuring consistent size and shape of bearing balls for optimal performance.

High Precision: Meeting strict tolerances and surface finish requirements critical for bearing functionality.

Efficient Material Removal: Enhancing productivity while maintaining quality.

The key components of bearing ball grinding include:

Grinding Wheel: The abrasive wheel used for shaping and finishing bearing balls.

Workpiece Holder: A mechanism that supports and aligns the bearing balls during the grinding process.

Regulating Mechanism: Controls the grinding wheel's movement to achieve precise results.

Types of Bearing Ball Grinding Wheels

Single-Disc Grinding Wheels: Designed for high-precision grinding of individual bearing balls.

Double-Disc Grinding Wheels: Ideal for simultaneous grinding of multiple bearing balls, improving efficiency and consistency.

Main Applications

Bearing ball grinding wheels are essential in various industries where precision bearings are required:

Automobile Industries: For producing high-quality bearing balls used in automotive applications.

Aerospace Industries: Ensuring reliable performance of bearing balls in aerospace components.

Industrial Machinery: Providing precision grinding for bearings used in various machinery.

General Manufacturing: Suitable for any application requiring high-quality bearing balls.